Culvert Rehabilitation

Infrastructure Rehabilitation

Culvert Rehabilitation is a key market segment for Nukote Coating Systems. Standard specifications for our products include highway and rail bridge deck waterproofing, protective systems for structural bridge components, architectural finishes for bridge superstructures, and tunnel linings.

Common Issues

Liner Capabilities

By combining a wide range of structural and elastomeric liners in conjunction with robotics and engineering services Nukote can create unique solutions for Culvert Rehabilitation. Aegis 360 Ringtech solution allows projects to be completed in a cost and time effective manner, increased quality control and consistency and versatility while having low operational footprint in both urban and remote locations.

-

Common Issue #1

Structural and Semi-Structural Integrity

When completed our structural liner effectively replaces the original host pipe with a 75-year design life and 25 year manufacturer’s warranty.

-

Common Issue #2

Liner Versatility

Large Diameter Culvert Rehabs are very suitable and easy to install with the Nukote Aegis System. Nukote has a hybrid two component liner where we tune and balance the flexural strength and flexural modulus properties to meet any required engineering spec. This allows these liners to be designed to meet any specification

Solutions Summary

Project Development

By us being involved in each step of project development we are able to provide support for engineers, installers and General Contractors. Nukote is highly engaged with their clients and contractors on any given project from concept to completion.

-

Common Solution #1

Protective Barrier Solution

Nukote elastomeric coatings are extensively used as a protective barrier for civil infrastructure projects such as bridges, highways, tunnels, and buildings. Our coatings protect against corrosion and abrasion and extend the life of critical infrastructure.

-

Common Solution #2

Culvert Life Extension

Most culverts have reached the end of their lifespan at 25-50 years. Nukotes Structural Liners is a cost-effective approach to extend the life cycle of the culvert for an additional 25 years without any replacement and prevents any further breaks or leaks from occurring.

Nukote Goal/Vision

Our vision is to be a leader in advanced coatings and materials by consistently delivering high-quality, innovative, and sustainable solutions that clients and contractors trust to protect a wide variety of substrates in numerous Industrial, Commercial, and Infrastructure application segments. NUKOTE has demonstrated commitment to innovation, customer satisfaction, and developing leading-edge coatings and specialty materials technologies. Through dedication and industry-leading expertise, we provide engineering and specification support that helps solve our customers’ biggest challenges, collaborating closely with them from initial project concept to job completion.

FAQs

The advantages of Polyurea coatings over CML are manifold such as increased flow, lower lining thickness, impermeability, bendability of pipes, resistance to hydrogen sulphide, crack bridging ability, higher tensile strength and rapid return to service.

ASTM E96, NSF61, NTPEP Tested, Greenbook Tested, ASTM D638, ASTM D1883, ASTM D3960, ASTM E-108, AASTHO HS20, M28 (Class 1-4)

Working together with our clients our engineer support team makes material recommendations and designs liner thicknesses that take into account different shapes and substrates (Concrete, Metal, Clay, Iron) need for structural integrity, high ductility, live load and traffic flow.

Polymeric Liners are best suited for lining of wastewater lines because of their extreme resistance to hydrogen sulphide. Polyurea coatings have found many uses for wastewater industry applications such as sewage digesters, clarifying tanks, internal and external linings, sewage tanks, secondary containment areas etc.

Polyurea is the reaction product of an isocyanate and amine which rapidly cures to an elastomeric film without the aid of catalyst. Polyureas appear to have better elongation and tear strength than polyurethanes where as polyurethanes provide more toughness. Structural grade Polyureas have better toughness and tensile strength. Short curing time (both polymers achieve their physical properties within minutes after application) is the primary advantage to both polymers. Insensitivity to moisture is the great advantage of polyurea over polyurethane.

Call for a FREE Evaluation or Estimate

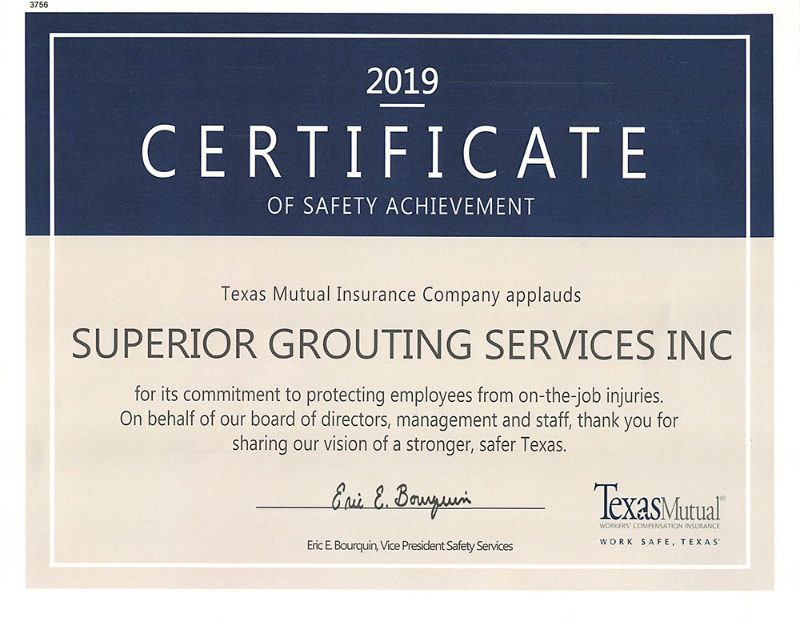

Superior Grouting is the original concrete leveling contractor and premier concrete raising services company in Houston – serving Texas, the Gulf Coast Region and surrounding States. We have more than 35 years of experience in concrete raising and leveling. Superior Grouting has state-of-the-art equipment and expert technicians to provide clients the best results.