Pipeline Grouting, utility lines and voids

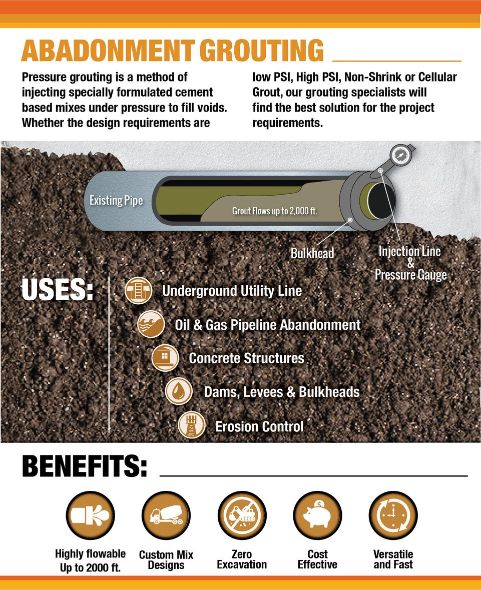

Pressure Grouting is the generic name applied to several applications requiring the pumping and injection of any number of variable grout mixtures.

Pressure Grouting is used primarily by the commercial, industrial, and municipal sectors as a filler for the abandonment of underground pipes, the grouting of annular spaces within underground utility structures and void filling.

Abandonment grouting service

Excavation and removal of abandoned underground pipes can be extremely expensive but abandoned pipes often cannot simply be left as is. In fact, in certain cases the law now requires that any abandoned pipe be removed or adequately grouted so that it will not collapse in the future and create voids that could cause settlement of the ground surface, roadbed or overlaying structure.

Pressure grouting can help reduce several problems caused by the presence of abandoned pipes:

- Migration of groundwater and hazardous fluids into the pipe

- Build-up of explosive gases in the pipe

- Collapse of the pipe, leading to settlement of the overlaying structures

Annular space grouting service

Annular space grouting is the process of filling the area between a host pipe and liner pipe in re-lining applications and very common for grouting casings with internal conduits in electrical duct banks.

It is important to remember when pressure grouting an annular space, it must be done right the first time, since there is not a second chance.

Pressure grouting annular spaces pose additional challenges. Superior Grouting has mastered the art of annular space grouting with over three decades of experience. We have extensive experience in placing sanded grouts and cellular grout mix designs.

design considerations

When grouting an annular space, it is very important to identify the following items prior to picking a technique and material:

Size of annular space, surrounding soil conditions and groundwater presence, distances between bulkheads, liner and host pipe injection pressure capabilities, liner and host pipe temperature specifications, heat of hydration of grout mix design, flotation calculations of liner pipe, slump or flow retention of mix over time, daily weather conditions, depth of structure, etc. Once the key project obstacles have been recognized the technique and grout material can be chosen.

Voidfill grouting service

Void Fill Grouting is typically called for when the roof of a void collapses, or a sinkhole or depression forms producing deformation of the ground surface or when pre-construction site testing uncovers such potential defects. The gradual deterioration of the void, usually over a period of years, most often appears as cone shaped depression, or hole at the surface which can result in damage to buildings, utilities and roads.

Voids can form under a variety of conditions both natural and man-made. Trash and rubbish buried during construction will produce a void as it decomposes. If the trash pit is located under a concrete slab, building footer or foundation, structural damage will often result from the subsidence. Sanitary and storm sewer pipes breaking will allow fill materials to be carried away producing underground voids. Water supply or drainage line breaks will cause the adjacent soils to be washed away. Flood plain areas subject to erosion, and poorly compacted soils around foundations, abutments, and retaining walls are just some of the common areas in need of void filling by way of a calibrated cement grout. The service of void filling and/or soil stabilization is often viewed as a preventive treatment.

Damage to structures from void formation may be minimal to severe. These damages may include cracking in foundation walls and floor slabs, cracking of brick veneer, vertical displacement of the structure with severe tilting, an inability to properly open and close doors and windows. Under extreme instances, complete structural failures can occur.

Filling of the void with a grout is conducted in one of several ways depending upon a variety of factors including location of the water table, the size of the cavity, its proximity to the surface and location in relation to structures.

One common and simple technique used to stabilize the subsurface and prevent subsidence is using a sanded cement grout slurry, cellular grout or chemical grout to fill the cavity below. This method employs the use of pneumatic or drilling equipment to install pipes that connect the surface to the void below. The pipes act as conduits to the subsurface void allowing grout to be installed. Grout pipes can be from 1-¼ inches up to 4 inches in diameter, depending on grout mixture and placement volume desired. Once the grout pipe or pipes are in place it is a simple matter to fill the cavity. With the use of shut off valves and pressure gauges it is possible to determine when the cavity has been filled. Once the cavity has been filled the pumps and valves are turned off and the grout allowed to cure.

Superior Grouting Services

Superior Grouting Services specializes in all pressure grouting applications. Our engineers can determine the best and most cost-effective solution to rectify nearly any situation.

Our Accomplishments