Cellular grouting

Cellular grout is an alternative name for

cellular concrete fill

. Cellular concrete is a type of controlled low strength material (CLSM). CLSM generally refers to flowable fill or mix designs specifically formulated for relatively low, but predictable, strengths. The “cellular” in cellular grout refers to the preformed cellular concrete foam used to generate the material. Instead of sand and stone aggregate, cellular Low Density Controlled Low Strength Material has uniformly-distributed air bubbles. Sometimes sand is used, but it’s at much lower quantities per cubic yard than traditional CLSM. This lowers unit weight significantly. Foaming is done either through truck batching or continuous generation.

Types of Cellular Grout

Cellular grout can be either pervious or non-pervious. We generate non-pervious material using CreteFoam preformed cellular concrete foam, which is manufactured by Richway Industries. Both types start with the same base 0.5 water :

cellular cement

ratio slurry.

Uses for Cellular Concrete

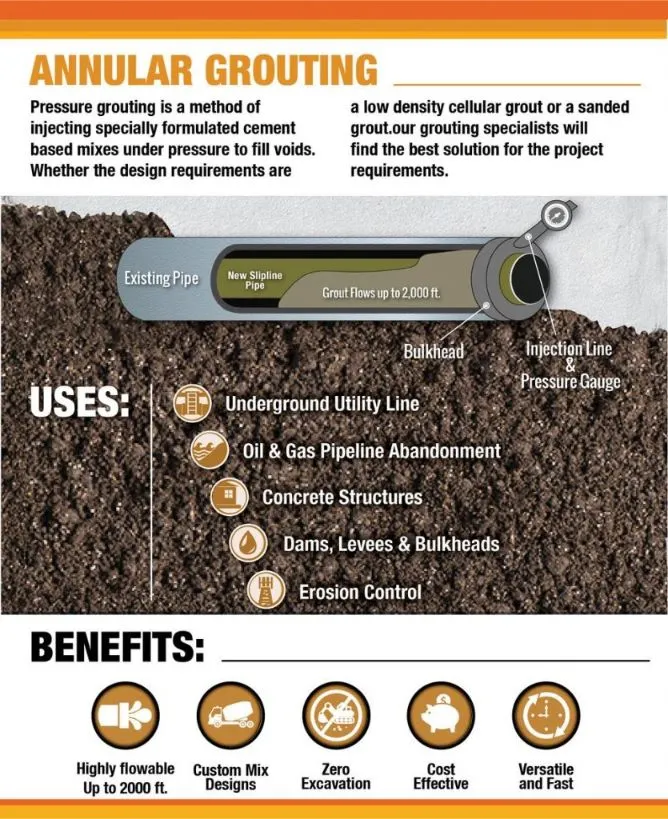

There are two primary drivers for using lightweight cellular concrete: load reduction and placement characteristics. On the lightweight side, cellular concrete is placed for load reduction; typical lightweight mass fills are installed around 20lbs/cuft. On the placement characteristics side, cellular concrete is used due to economics in utility grouting applications in that it can be pumped very far (thousands of feet) at very low pressures. This facilitates annular space grouting and abandonments of much longer runs compared to traditional grout materials.

Typical Neat Mix Designs

Neat mix cellular grout is generated using a straight slurry, usually 0.50 water : cement ratio. For applications which need to be poured on slopes, 0.45 water : cement ratio slurry can be used. The

slurry grouting

is blended onsite with pre-formed foam such as CreteFoam, either in a ready mix truck or in-line, depending on the project volume & other constraints.

Cellular concrete typically ranges from 20lb/cuft wet cast density up to around 90lb/cuft. These densities provide strengths from around 50psi to greater than 1,000psi. Density is effectively infinitely variable within that range. There’s a relatively linear relationship between density and compressive strength.

Relatively common mixes are 20PCF, 30PCF and 70PCF. 20PCF wet cast density is the go-to mix design for maximum load reduction. Pervious cellular grout is used in areas where low unit weights are required, and buoyancy can’t be balanced by overburden. 30PCF is a relatively common mix for pipe abandonments, annular space grouting and other utility-related work.

70PCF material is also used to provide weight reduction compared to traditional CLSM or other fill materials when buoyancy must be absolutely avoided. Pervious cellular concrete must be protected from adjacent soils with geotextile fabric. Superior Grouting uses 68PCF wet cast density material in cases where pervious cellular concrete can’t be used, and buoyancy is a concern. 1,000psi compressive strength is required for some annular space grouting work. Superior Grouting uses 70PCF west cast density material to meet this specification.

Typical Sanded Mix Designs

Sanded mixes are used to economically achieve high wet cast densities. The base slurry for sanded cellular grout consists of around 2,000 pounds of sand per cubic yard, 600 pounds of cement and around 800 pounds of water.

Sanded base mixes can be used to absolutely ensure no buoyancy of cured material; the oven dry density of 75lb/cuft material is 68lb/cuft, ensuring that regardless of how dry an environment is, there are no chances of material buoyancy. 75lb/cuft sanded lightweight foamed concrete breaks around 200psi at 7 days and 300psi at 28 days.

A limitation of using sanded mixes is pumpability; sanded cellular concrete can’t be pumped nearly as easily as neat mix cellular concrete. When specifying cellular grout, it’s best to leave the mix design up to the specialty contractor. Typically, specified characteristics are a wet cast density that’s +/- 5lb/cuft, and a minimum strength in psi at 28 days.

Cellular grout is an engineered portland cement slurry combined with precise amounts of density controlled foam. The portland cement slurry and foam are mixed producing a lightweight mixture containing uniformly distributed air cells. In it’s rigid form it can be thought of as cement based grout having air as the aggregate. Density can be varied from 20-120 lb./ft3. Compressive strength ranges from 20 to 3,500 psi. are available. Cellular grouting is becoming more and more commonly used and accepted within the engineering and construction community as a technology for filling voids. Some relevant applications include but are not limited to: pipe abandonment, voided slab fill, decommissioning and abandonment of underground tanks and structures, mine stabilization and abandonment, and annular space grouting.

Superior Grouting Services

Superior Grouting is a certified cellular grout installer. We work with owners, engineers, and contractors to develop project solutions using

cellular foam concrete

. References and

cellular grouting costs

are available upon request.

Our Accomplishments